Our Technology in use

Applications

See examples of how our technology can be put to use in a large range of different applications, and read real life case studies of how we’ve completed successful fully digitized inspections of confined spaces.

Maritime & Offshore

Vessel surveys and inspections are a critical part of maintaining efficient modern global trade and prevent harm to people and the environment.

Ensuring that vessels continue to be safe to operate over their lifetime can be an expensive and time-consuming activity with its own inherent risks. Our drone technology provides an alternative to the use of scaffolding and rope access for carrying out internal inspection of vessel cargo tanks and other interior areas.

Related case studies

Oil & Gas

The culture of Oil & Gas is based on safety first and this is woven into the DNA of the industry.

With increasing cost and time pressures our clients need to find new and innovative ways to meet the demands of the industry without sacrificing the decades of improvements in safety culture. Our drone technology is a key tool in minimizing the need to send people into hazardous areas to carry out asset integrity inspections. The unlimited flight time capabilities means that you are not limited in your visual coverage of the assets.

Related case studies

Infrastructure

Our industrial society depends not just on the development of new infrastructure, but also the inspection and maintenance of existing assets.

Failure in infrastructure assets can be catastrophic and lead to loss of human life and significant costs to repair and recover. Our drone technology can be your tool to inspect and track the long-term condition of your assets, enabling you to use data to identify problems before they materialize.

Related case studies

Commodity Cargo

Silos, elevators, and bins are commonly used to store commodities such as grain, food products, cement, and other bulk materials.

These assets often need to be regularly visually inspected for corrosion and other structural anomalies. With a large number of these types of assets, our drone technology can provide a quicker and more flexible solution for both general and detailed inspections of the internal structure.

Power Generation

With the need to ensure continuous and stable power to billions around the world, new inspection and maintenance technologies are key to safeguard facility operations.

Our drone technology can act as a force multiplier in power facilities where manning levels are usually minimal. An increasing drive towards renewables is also opening new opportunities to build in autonomous technologies at an early stage.

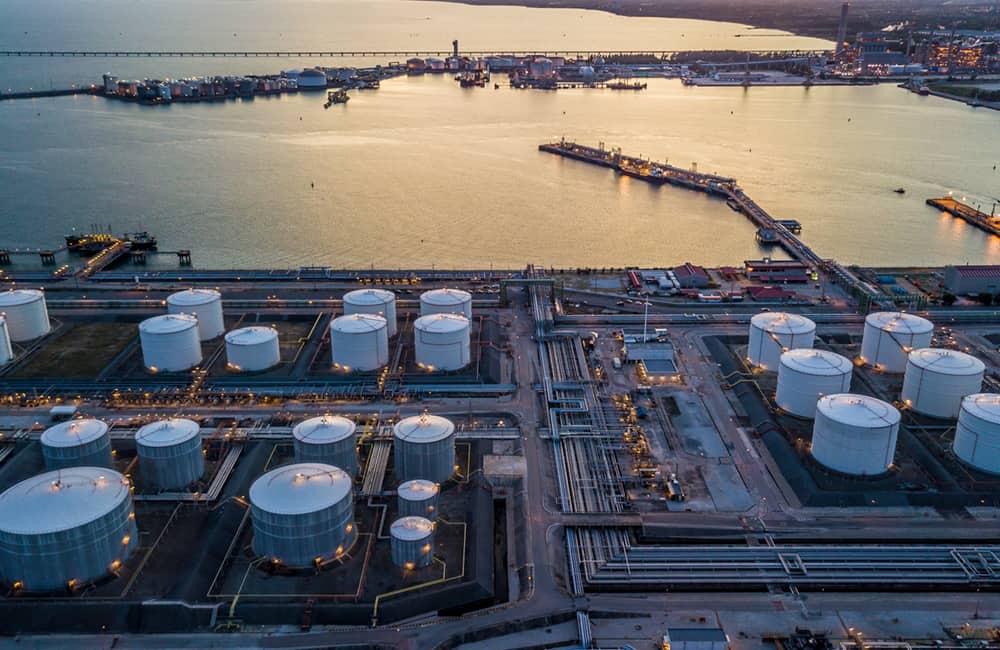

Port Facilities

Port facilities around the world enable global trade and provide a necessary buffer to shocks in the supply and demand for many commodities.

Therefore, inspection and maintenance of these assets contribute an important insurance against risk to global trade. Our drone technology is compact and can be made available at site for easy deployment. The remote viewing capabilities minimizes the need for quality assurance inspectors to be present on site or enter the confined space.

Related case studies

Other reads

In order to ensure the safety and integrity of industrial assets, inspection technology must consist of two key parts: Data acquisition. The right data needs to be collected with sufficient coverage and precision. Data science. How can we turn large amounts of data into insights and...

In part 1 we looked at factors that influence camera image quality – beyond the number of megapixels, being the parameter typically used to highlight image quality potential. Now let’s put it into the context of indoor drone inspection. Starting drone inspections means you must...

Caused by or at least aggravated by the COVID-19 pandemic, the shipping world has seen a surge in the need for remote inspection in the last few years. Fewer hands on deck, increased work pressure and tight work schedules puts seafarer safety at risk and may jeopardize proactive inspection and...

OSEA (Offshore Southeast Asia) has had a virtual break but is now back in real life as a new and refreshed trade show. At the forefront of offshore oil, gas and emerging zero carbon energy sources, OSEA keeps the focus on developments in oil and gas and showcase opportunities in offshore wind and...

The AUTOMA Oil & Gas Automation and Digitalization Congress has quickly become one of the most anticipated events in the energy sector, this time listing over 170 companies and 65 top speakers. It is a perfect arena for showcasing solutions and services in Oil & Gas, networking with...

The annual SPRINT Robotics World Conference for Inspection & Maintenance Robotics is the leading global event for robotics for inspection maintenance and cleaning. It is a unique event where asset owners, operators, technology developers and -suppliers as well as service suppliers from all...

The world’s largest Energy Drone & Robotics event The ENERGY DRONE + ROBOTICS SUMMIT is where the industry gathers for the latest ideas, observations and predictions about the business and technology of unmanned systems, automation and data/AI in energy & industrial operations. It...

Using indoor drones to obtain inspection footage improves safety, saves time and reduces cost. But the image quality must be as close as possible to human eye perception for an effective inspection that meets standards and doesn’t miss any details. This inspection drone has a 4K camera – but...

StocExpo is the largest and longest running liquid storage event in the industry, and is now returning to the Rotterdam Ahoy as a great opportunity to inspire, connect and share knowledge. Future. Delivered. StocExpo provides a platform for the bulk liquid storage industry that delivers valuable...