Cloud-based inspection data tool

Scout Portal

The Scout Portal is our powerful cloud-based tool for inspection data management. It has built-in SLAM and visualizes location-tagged payload data in a 3D point cloud.

Visual inspection data, accessible from anywhere

Global accessibility and security for your inspection data

The Scout Portal is hosted on an industry-standard cloud platform (Microsoft Azure) which means it is accessible anywhere and requires nothing but a browser and an internet connection to work. This strategy also comes with super-reliable availability and world-leading two-factor authentication.

With a very large amount of online storage you don’t have to worry about safe storage and backup of your inspection data.

Live-streamed inspection

If the Scout 137 Drone System is connected to the internet, the inspection can be streamed live via the Scout Portal to allow remote participation for stakeholders and off-site team members to observe, advise and collaborate.

Cross-functional team collaboration

Live streaming opens up a whole new dimension of cross-functional, distributed team collaboration and more efficient, data-based decision making. In many cases it will be crucial to ensure full data coverage, reduce time on-site, and avoid re-visits. Need a corrosion expert to sit in during the inspection? Yes, you can.

Built-in SLAM

All data from ScoutDI payloads is location-tagged by the onboard LiDAR of the Scout 137 Drone. Via the Scout Portal’s built-in SLAM pipeline, a visualization of the asset is automatically generated as an interactive 3D point-cloud, with POI locations and flight path tracking.

You can choose color mapping based on elevation or reflectivity, and several color palettes are available. Point-size and -opacity can be adjusted to your preference, contributing to optimize the rendering of your data.

All your inspection data in one place

Live-streamed inspection data is automatically stored in the Scout Portal and it’s easy to upload full-res data after the inspection. You can also upload data from other sources such as digital cameras, mobile phones, ROVs and other drone systems.

This is a very handy option for acquiring secondary footage from the inspection target, handheld from the on-site crew, additional outdoor footage and even underwater footage.

You can have everything related to the same inspection job organized side-by-side.

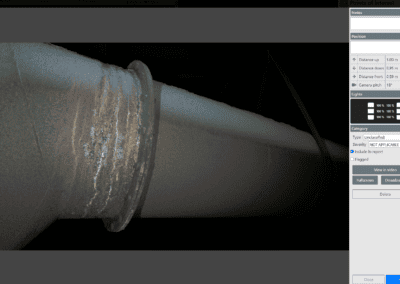

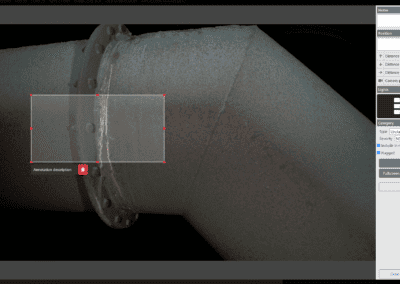

Data evaluation, annotation and reporting

All inspection data can make use of the tools available in the Scout Portal, which includes review, annotation and reporting and analysis tools.

You can evaluate data from all sources, add POIs and write annotations to them. The video timeline, point cloud and “edit findings” views allows a flexible workflow where you can access the same events in several ways, whether you choose to work chronologically along the or need to focus on specific locations inside the asset.

The Scout Portal makes use of Machine Learning (ML) to automatically detect and classify anomalies and currently has corrosion detection available. There is also an API for data integration to existing ecosystems like Asset Management Systems, digital twins etc.

The bottom line

The Scout Portal is your ticket to realizing a new level of efficient, data-driven decision-making for structural integrity management and predictive maintenance.

The Scout Portal is our powerful cloud-based tool for inspection data management, offering inspection replay and live streaming. All inspection data from Scout 137 payloads are location-tagged and illustrated in the point cloud in the session view. Data from other sensors can be uploaded and included in any inspection.

In this short video, you can see the drone inspecting internal features of a large above-ground storage tank. These perspectives are offered:

✅ Scout App, as seen by the pilot while flying

✅ First-person view of Scout 137 Drone, via the Scout Portal

✅ Third-person view via mobile phone and another drone

Click in the gallery below to view larger versions of the images. Use arrow buttons to navigate and ESC to exit the viewer👍

Click here to download a zip file with 4k POI photos from this inspection.

Inspection images: Storage Tank

Storage tank inspection with Scout 137

Scout 137 approaches a large pipe, approximately 13m above the floor.

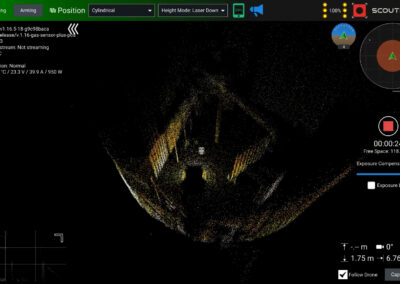

Scout App, point cloud

Screenshot from the Scout App, as seen by the pilot while flying. The point cloud can be freely zoomed, panned and rotated.

Scout App, video stream

Another screenshot form the Scout App. The pipe is clearly seen in the mini-map. Telemetry data bottom right.

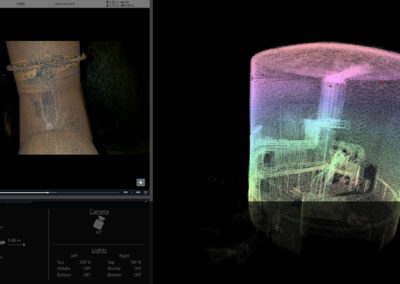

Scout Portal, session view

Inspection replay in the Scout Portal. The point cloud can be freely zoomed, panned and rotated. POI shown with red markers along the flight path.

Scout Portal, POI view #1

Inspection replay in the Scout Portal. Zoom and pan 4k photo in full-screen or open video in this exact point in the timeline.

Scout Portal summary of benefits:

✅ Inspection replay accessible from anywhere

✅ Upload data from any source

✅ Data from Scout 137-carried sensor location-tagged in 3D point cloud

✅ Live-streaming for remote participation

✅ Fast and easy collaboration with off-site personnel

✅ Promotes efficient, data-driven decision-making

✅ Easy review and annotation of inspection findings

✅ Dynamic reports hyperlinked to Scout Portal

✅ Cloud data storage

✅ ML-based data analysis

✅ Data integration via API

Watch this 2-minute video for a quick for a quick introduction of the full system

Case studies

Case StudyUnlimited flight-time provides optimum working conditions and maximizes safety, efficiency and data quality. Executive summaryTDBR...

Case StudyUnlimited flight-time provides optimum working conditions and maximizes safety, efficiency and data quality. Executive...