A confined-space inspection drone system with unlimited flight time

Scout 137 Drone System

The Scout 137 Drone System has been specifically designed for safety and to give you control, coverage, and high-quality data for indoor inspections in industrial environments.

Confined Space Inspection Drone System

The Scout 137 is designed for GPS-denied, hostile environments with little or no ambient light. Atmospheres may be toxic, with little oxygen. There may be dust, debris, risk of falling and entrapment. Such places are often not suitable for human entry. But they’re still in need of inspection and structural integrity assessment.

It’s easy to find motivation for using indoor drones instead of human entry in many indoor industrial inspection tasks. But still, getting the right tool for the job is vital. To perform a safe inspection and gather good data, you need a tool that lets you focus on the job, provides the best possible data and enables easy sharing and reporting.

Watch the video and read on to learn more about the Scout 137 Drone System.

New! UTM Payload available now.

System benefits:

✅ Unlimited flight time for stress-free inspection

✅ Onboard 3D LiDAR for safe operation, stable flight and good data

✅ Location-tagged inspection data, no lost POIs

✅ Live streaming of Full HD inspection video

✅ Cloud-based data management and analysis solution, API for data integration

Watch this 2-minute video for a quick product introduction!

Click below to learn more about the Scout 137 Drone System

Scout 137 Drone

Ground station

Scout App & controller

The full kit – what’s included

Scout 137 indoor inspection drone

Onboard 3D LiDAR keeps humans safe and provides better data

Indoor industrial spaces often suffer lack of GPS coverage, leaving most off-the-shelf drones without the reference needed to maintain stable positioning. If there’s also a lack of light, optical sensors and Visual Positioning Systems (VPS) will not work. You’ll be flying full manual and may not even see the drone properly! It will be subject to competing, uncoordinated influence from the pilot and the environment. The flight path may become jumpy and irregular, introducing motion artifacts into your inspection data and worst-case causing a crash.

3D LiDAR to the rescue. The Scout 137 Drone is designed around a 3D LiDAR sensor that enables the drone to map its surroundings in real time, with sub-centimeter accuracy. This data is used for the safe and stable flight, as a visual aid to the pilot and for location-tagging all the inspection data from your flight.

Patent-pending technology ensures that live sensor data is translated into a 3D map of the environment, including the drone’s position and heading. Joystick input from the pilot is combined into the processing and “corrected” by sensor data before affecting motor power.

The Scout 137 drone knows immediately if it’s being unintentionally displaced by a gust of air, propeller blast or other factors, and is able to correct that itself. The result is a drone that is easy to fly, maintains position when no manual input is provided, and moves with smooth and even motion. It can also avoid obstacles and perform “smart moves” like sliding along walls at a fixed distance. Even with curved, irregular surfaces.

No human entry and location-tagged data

Drone inspection in confined industrial environments with just the drone camera as visual aid, can be a daunting task. Self-similarity, repeating structures, lack of peripheral vision and insufficient ambient light soon becomes distracting and bewildering to the pilot. And sometimes, flying beyond visual line of sight (BVLOS) is the only safe option.

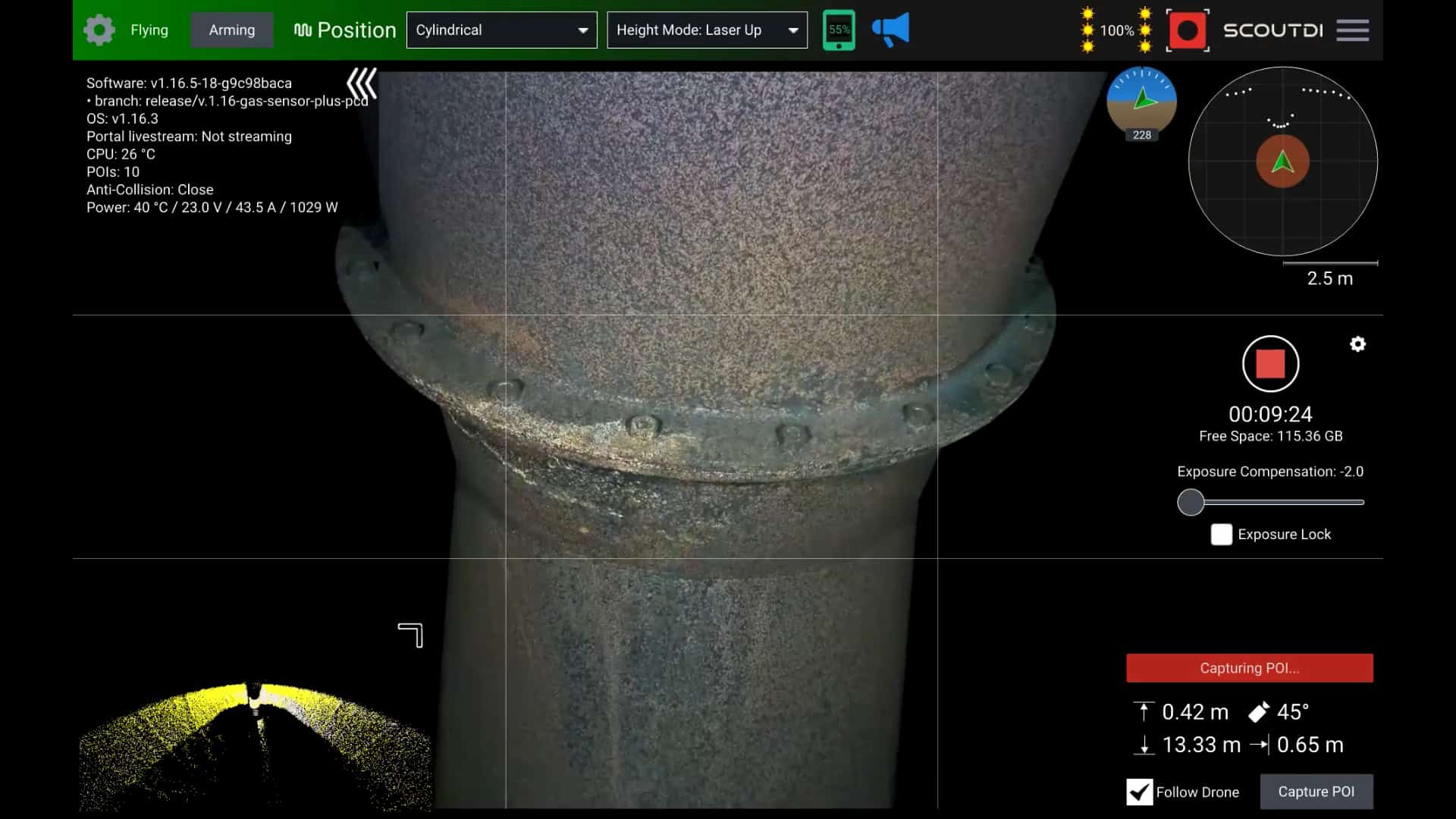

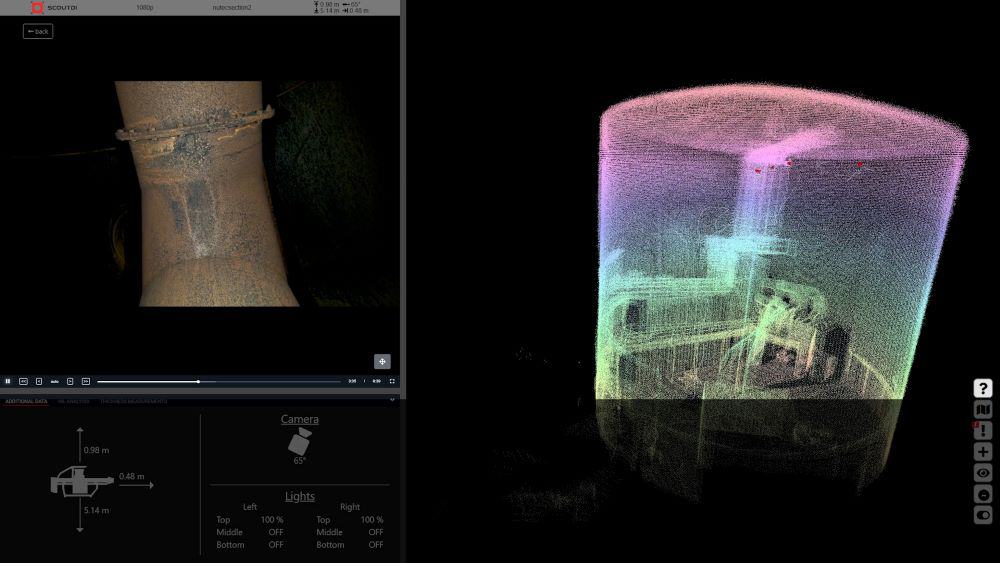

The Scout 137 Drone’s 3D LiDAR data is also used to render a 3D situation map in the Scout App. This 3D map is shown picture-in-picture with the drone’s camera feed, and can be freely panned, zoomed and rotated. It is an indispensable visual aid to the pilot, showing the drone’s position and heading inside. When the pilot gets this situational awareness of the space, navigation becomes easier and stress is relieved.

Since position and heading in 3D space is available at any instant, all inspection data is location-tagged on-the-fly. This makes data review and reporting in our online inspection data portal – the Scout Portal: For everything you see on the video (or photos), there’s a position. So you know exactly where it is in the physical asset.

Read more about the benefits of 3D LiDAR here.

Gimbal-stabilized 4K camera and powerful LEDs

With LiDAR-powered stability comes crisp visual inspection data with consistent and smooth framing. The onboard 4K camera is mounted on a 2-axis stabilized gimbal that is pitch-adjustable between+/- 90 degrees, to cover inaccessible ledges, ceilings etc.

This also becomes useful during BVLOS operations, tilting the camera freely helps a lot when trying to position the drone for retrieval via a narrow opening, for example. With the current camera angle displayed on the tablet, this becomes a good visual aid to the pilot at critical stages.

4K preview at your fingertips

A much appreciated function of the Scout 137 Drone is the 4K preview. Every time you click the controller’s designated POI button, a POI is created in the inspection dataset and a 4K preview thumbnail appears on the screen. Tapping the thumbnail opens the photo in full 4K resolution, you can zoom and pan it freely for close examination.

Read more about 4K preview in this article

Onboard LEDs

The onboard lighting rig provides over 10 000 Lumens of light and has flexible control options to let you make the most out of it: Depending on the situation, you want even lights but need to dim them now and then to avoid glare from specific surfaces. Or sometimes you may need to create shadows to emphasize thin cracks.

Light presets

The Scout 137 has seven different Light presets available directly from the controller. The pilot can cycle through all of them with one designated button to quickly and easily decide which light setting is currently the best, without taking eyes off the drone or the screen.

The Scout 137 Drone is made to simplify your indoor inspection duties and improve your data-driven decisions. Now you can inspect the drone! The 3D model allows you to look at it from any angle, zoom in and out and read the text captions.

- Click ▶️ to load model.

- Fullscreen is available.

- Navigate annotations via the numbers.

- Click and drag / swipe to rotate.

- Ctrl/shift for zoom and slide.

Scout 137 Drone specs

| Dimensions, drone | 613mm × 382mm × 303mm (L×W×H) |

| Dimensions, transport case | 676mm × 525mm × 378mm (L×W×H), regular checked baggage |

| Weight | 3.2 kg |

| Camera resolution | 4K video, 3840 x 2160 @ 30 fps |

| Lighting Intensity | Over 10,000 lm |

| Camera Gimbal | 2-axis stabilized, ± 90° pitch |

| Tether Length | 40 m |

Tether and Ground Station

The ground station provides power, a control connection and a data network via the tether.

While other indoor drones rely on batteries to remain flying, the Scout 137 uses a different approach supporting longer-haul inspection work. The Scout 137’s tether system supplies power to the drone and allows stress-free inspection with no limitations on flight time. No need to worry about changing batteries. You can take your time while flying and make sure you capture the right data. Need to discuss something with your team mate while working? The drone will wait, mid-air, steady as a rock.

The tether also provides a robust wired data link, where location-tagged inspection data flows back to the ground station and can further be streamed live to the Scout Portal, when an internet connection is present.

Tether

The tether itself is a custom made high-quality product. It has excellent cut resistance and a smooth outer surface to be able to slide over beams, rails etc. without catching. It has high-visibility coating and halogen-free flame retardancy as recommended by its application.

The tether easily plugs in to the ground station and the drone, and is secured with carabiners that relieve stress and secure the connection. The tether is rolled up on the provided coil and stowed away inside the ground station box after use. Current tether length is 40 m.

Ground station

The Ground Station connects directly to wall power outlets, generators or battery packs. When it’s required, we also provide a suitable battery solution with the system, mounted in the same type of case as the other components.

The ground station receives all control signals from the pilot to the drone, via a fully-wired connection, completed by the tether. It can also be connected to the internet to allow live streamed inspection. Please read on for more about this!

Ground Station Specs

| Dimensions | 385mm × 440mm × 245mm (L×W×H) |

| Weight | 8.75 kg |

| Input Voltage | 200 – 240 VAC, 50/60 Hz |

| Internet connectivity | LAN/Ethernet (built-in) |

| Ingress Protection | (Made to the specifications of IP54) |

The Scout Portal provides full inspection replay and live streaming

The Scout Portal is our cloud-based data management service. It allows storage, analysis, visualization and reporting of all your inspection data in one place. You can even upload visual data from other sensors, for example ROVs or outdoor drones, to the same interface. Brilliant for complex, comprehensive inspections and reporting.

The Ground Station can be connected to an on-site LAN, allowing live inspection streaming to the Scout Portal. If there’s 4G/5G coverage, you can even provide a connection via your phone.

Live inspection streaming is a useful work mode that allows inspection teams on-site to cooperate with off-site stakeholders live during inspection. You can invite certification authorities or asset owners to sit in and observe, without travelling on-site. This allows more effective decision-making and can shave hours and days off the inspection time. You might have an action plan ready before landing, and eliminate the need for re-visits.

The Scout Portal

The Scout Portal is a powerful cloud-based tool for the live-streaming, capture, storage and analysis of data for your confined space inspection needs.

Scout App & Controller

The pilot operates the drone via the Scout App and a controller

In summary, the connection chain between pilot and drone looks like this:

Pilot -> controller and tablet/Scout App -> connection hub -> ground station -> tether -> drone.

The controller connects to the tablet/Scout App via a fully wired USB connection. The Scout App provides full control of the drone’s systems and displays the camera feed and 3D LiDAR point cloud in real time. Due to the autonomy and navigational aids built into the drone system, you will be able to perform advanced flight patterns with simplified flight controls.

The user can register “normal” or “flagged” POIs using short or long clicks on the right-hand index finger button, respectively. Whenever a POI is created, a thumbnail photo of it is shown in the bottom right corner of the tablet. Clicking this opens a full 4K preview photo of the POI, allowing the pilot to consider further action while still on-site, flying.

Fully wired drone control

Metal structures in buildings can create problems for wireless transmission of data and control signals. Therefore, we have chosen to implement a robust wired connection all the way from the pilot’s controls to the Scout 137 Drone.

The controller and the tablet both have wired connections via a hub to the ground station. The ground station forwards all control signals to the Scout 137 Drone via the tether.

This prevents multipath distortion and interference from other sources from compromising drone control.

Controller Specs

| Dimensions | 125mm × 159.4mm × 66mm (L×W×H) |

| Weight | 306 g |

| Battery | Up to 23 hours |

Tablet Specs

| Dimensions | 170mm x 243.5mm x 9.9mm |

| Weight | 653 g |

| Display | 1920 x 1200, 10.1 inches |

| Ground station connectivity | Wi-Fi or USB |

| IP rating | IP68 |

| Battery | Up to 15 hours, replaceable battery |

📢 “Never lose your way, never lose your data and never lose your drone”.

A Serious Tool for indoor inspection

Quality begets quality

Our product is a cutting-edge, fully digitalized drone-based system for safe indoor inspection of industrial spaces. The system allows you to focus on the job and also has clear advantages for beyond-line-of-sight (BVLOS) applications.

Along with the Scout Portal, it is an end-to-end inspection data chain that extends beyond the memory card to fully enable the digitalization of your industrial inspection and predictive maintenance activities.

Review system benefits:

✅ Unlimited flight time for stress-free inspection

✅ Onboard 3D LiDAR for safety and stability

✅ Location-tagged inspection data, no lost POIs

✅ Cloud-based data management and analysis service

✅ Live streaming of Full HD inspection video

Equipment included with purchase

The below hardware is included when purchasing a Scout 137 Drone System.

All cables and connectors needed to operate the system are provided, in addition to some spare parts and field tools.

All purchases are bundled with a one-year license for the Scout Portal, our cloud-based data management, analysis and reporting solution.

Even though the Scout 137 Drone System is easy to use, every purchase includes full pilot training including setup and troubleshooting, to enable confident and safe operations with the system.

Scout 137 Drone

Ground Station

Rugged tablet with Scout App

The Scout 137 Controller

High-visibility chest harness

Scout Portal subscription

Learn More

Scout Portal →

The Scout Portal is a powerful cloud-based tool for the live-streaming, capture, storage, and analysis of data for your confined space inspection needs.