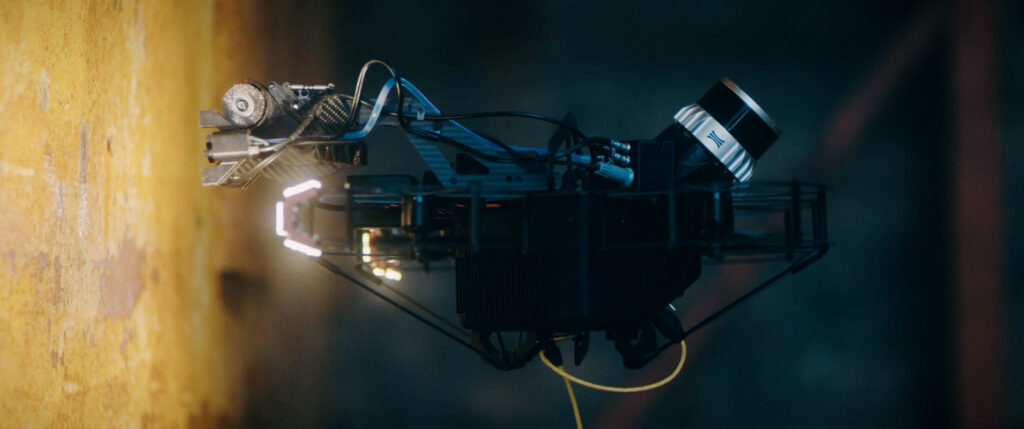

Designed for high-precision data capture in the most challenging environments, the new Scout 137 combines unlimited flight time, survey-grade LiDAR, optical zoom, and smarter UTM workflows in one robust, field-ready platform.

What’s New in the Scout 137 — And Why It Matters

Everything new in the next-generation Scout 137 is based on real-world customer challenges and designed to overcome those challenges with precision and efficiency.

Survey-Grade 3D LiDAR (OS0-128, 128-beam)

The foundation for confident navigation. With 128 beams, 35–100 m range and a 90° vertical field of view, this LiDAR system delivers real-time mapping and obstacle detection—even in large or geometrically complex spaces. SLAM positioning keeps you oriented, and precise localization enables more systematic data collection.

New, 3.5x Optical Zoom Camera with Autofocus

Get the detail you need—without pushing the drone into tight spots. The new 3.5x zoom camera allows safe stand-off visual inspection of welds, cracks and corrosion. It also works around obstacles, letting you inspect targets that aren’t directly accessible, saving time and reducing risk.

UTM Payload with Integrated Surface Preparation

Designed for seamless action in close contact. The head of the patent-pending UTM Payload combines spot preparation and ultrasonic measurement in a single, stable docking. Real-time parameter control gives clean A-scans on a variety of surfaces. And with servo-controlled magnetic release, the drone detaches cleanly—minimizing stress on the airframe and improving flight safety. allowing the drone to disengage without shifting its entire frame. This protects the drone and improves overall safety by avoiding the excessive force otherwise needed to break magnetic contact.

Improved Flight Performance

A lighter frame, optimized inertia distribution, and enhanced thrust provide tighter control and excellent stability—critical for navigating narrow spaces and maintaining sensor accuracy.

Extended Tether Range (Up to 60m)

Operate further from the ground station without sacrificing performance. Perfect for large tanks, silos, or long corridors where reach matters.

Tether Launch and Recovery System (TLRS, pat.pend.)

Deploy and retrieve the drone through narrow hatches using the tether alone. This minimizes risk during access and extends the range of viable inspection environments.

Improved Pilot Interface and Control

A larger screen and streamlined interface make the new Scout 137 easier to fly and faster to operate. Clearer visuals and controls reduce workload and support better decisions, even in challenging conditions.

Field-Ready and Serviceable

The next-generation Scout 137 is easier to assemble and service in the field, with a ruggedized Ground Station making it ready for demanding industrial conditions.

Real-World Benefits

In the video above, you’ll see the system performing live in a rust-stained industrial environment with structural obstacles. The drone maintains stable flight, avoids collisions, and carries out UTM inspections with integrated surface prep—even in tight spaces where human access is blocked. The zoom camera helps overcome visual obstructions, letting inspectors examine areas they can’t fly directly toward.

Every new feature is designed to remove friction: less repositioning, fewer interruptions, higher data confidence.

Smarter Data from Smarter Flights

The next-generation Scout 137 produces high-quality 4K imagery, 3D LiDAR data, and UTM readings in a single, synchronized mission. When paired with the Scout Portal, you get full spatial context for every POI and UTM—enabling fast assessment, team collaboration, and automated reporting.

Looking to organize, analyse, and share the results of your inspections? Scout Portal is the natural partner—designed to turn Scout 137 flight data into insights and action.

Why the Next-Generation Scout 137 is the Right Move

If you’re using manual tools, battery-powered drones, or unstable systems in confined spaces, the Scout 137 solves real-world pain points:

- Unlimited flight time for uninterrupted missions

- Better close-range stability and obstacle awareness

- Prepare and measure surfaces in one pass

- Zoom in safely when flying closer isn’t possible

- Gas sensor included – an added layer beyond standard safety precautions.

- Improved UI and general pilot experience.

Whether you’re inspecting tanks, ship hulls, hydropower shafts or other hard-to-access infrastructure, the next-generation Scout 137 brings confidence to the job. 👍

Curious what the Next-Gen Scout 137 can do for your inspections?

Contact us to learn more👍