Please have a look at this video, showing a simulation of the Scout137 Drone inside a mine passage. You can see how the drone takes off and rises towards the ceiling, before proceeding further into the passage.

Parts of the sequence consists of 3D-rendered surfaces with advanced textures and lighting, other parts show a Scout App dashboard with 3D point cloud, camera feed and flight info.

Pretty cool, yes?

Real-time simulation of drone inspection

Here’s the coolest part: This is not an animation, but a real-time simulation.

The mine is a modeled 3D environment created for the purpose of simulating a mine inspection. It is the output of a semi-procedural method for generating tunnels of arbitrary length and shape based on a Bezier curve. The rock textures are based on photogrammetry data.

We simply uploaded the mine model with textures to the Scout Simulator. In the simulator, we can choose external camera angles, natural and artificial lighting, and the drone that you see is a 3D model of a Scout 137 Drone. So far, it could have been an animation.

But the rest is a real-time simulation of the Scout 137 Drone in a virtual environment, run on a PC in ScoutDI headquarters in Trondheim. Pilot input is given via a controller plugged into the PC and all input from the pilot is considered, along with simulated values from all flight sensors: IMU, LiDAR, vertical lasers etc.

These components have been modeled to respond in a realistic way to the environment the drone “flies” in. So for example, the LiDAR model “sees” the topography of the mine, the shape of every little bend and corner, every little virtual rock.

The simulated IMU (Inertial Measurement Unit) responds to the drone’s movements via a physics model matching the major Newtonian forces that would be acting on the drone, from the simulated motors and propellers, and the exterior, on Earth.

Software-in-the-loop

The sensors feed their data into the exact same software that is normally running on the Scout 137 Drone. But in this case, it is running in a shell on our simulator PC. This type of testing is often called software-in-the-loop testing (SIL) and is a great way to test production code before deployment on the real drone. In simulation we can test edge cases and many different synthetic environments to ensure robustness of the drone´s control system.

The parts in the video where you can see the Scout App “screen” with point cloud, mini video feed and flight details, are also from the exact same software that is normally running on the pilot´s tablet. But in this case, it is running on our simulator PC. Heard it before?

One other thing you may notice is that the point cloud is based on online SLAM and is denser than before. The result is a more realistic and useful LiDAR rendering, that together with information about altitude, distance to ceiling and nearby surfaces, provides the pilot with a more complete situational awareness of the flight.

This last part is also representative of a coming update of the Scout137 and the Scout Portal, that will happen in real life.

There are several applications for the Scout Simulator:

Internally, it is a development tool used for testing new software, SLAM and other algorithms. We test all software releases in the simulator (and in real life).

Externally, it is a suitable and forgiving training environment where you can train pilots from scratch to get used to flying the drone in different environments. On a longer term, customer may also use it to plan and test inspection jobs, uploading models of the environment to the Scout Simulator.

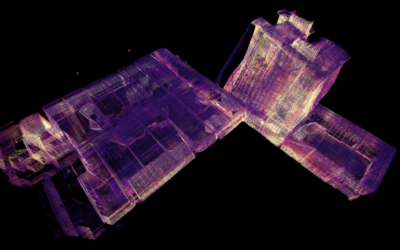

3D point cloud

We’ve also published this 3D model of our semi-procedurally generated mine tunnel. You can freely play with it: Zoom in and out, rotate and pan (hold Shift to pan left, right, up and down). Click the symbol in the bottom right corner to open in full-screen.

The POIs in the model are:

- Take-off and landing site: The flight started and ended here.

- Ground Station: The Ground Station was placed on this spot.

- Return point: The drone did not proceed beyond this point.

POIs 1 and 3 mark the end points of the flight, thus only partial coverage extends beyond those two points.

What do you think?

If you have comments on SIL in general, how we use it, the video or the point cloud, let us know on LinkedIn 😊👍

Tell us about your indoor drone inspection case!

Asset owner, operator or service provider, considering to move into indoor drone inspection or expand your business portfolio or toolkit? If you’d like to discuss an application of our Drone System, contact us via the form below!