Total inspection. Total Confidence

The Next-Generation Scout 137 Drone System

Built for endurance, automation and data-driven insight

Proven Leadership

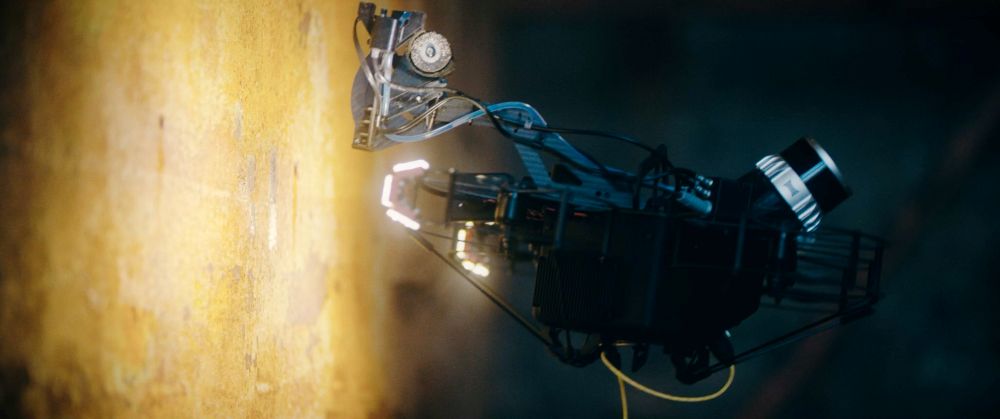

Confined-space inspections are essential, but traditional methods are slow, costly and risky. From the very first generation, we designed the Scout 137 system around tethered endurance and scanning 3D LiDAR as core features.

These choices created the foundation for automation and structured data collection. With inspection payloads like UTM and Gas Sensor, our proven concept continues to lead the way in safer, smarter and more efficient inspections.

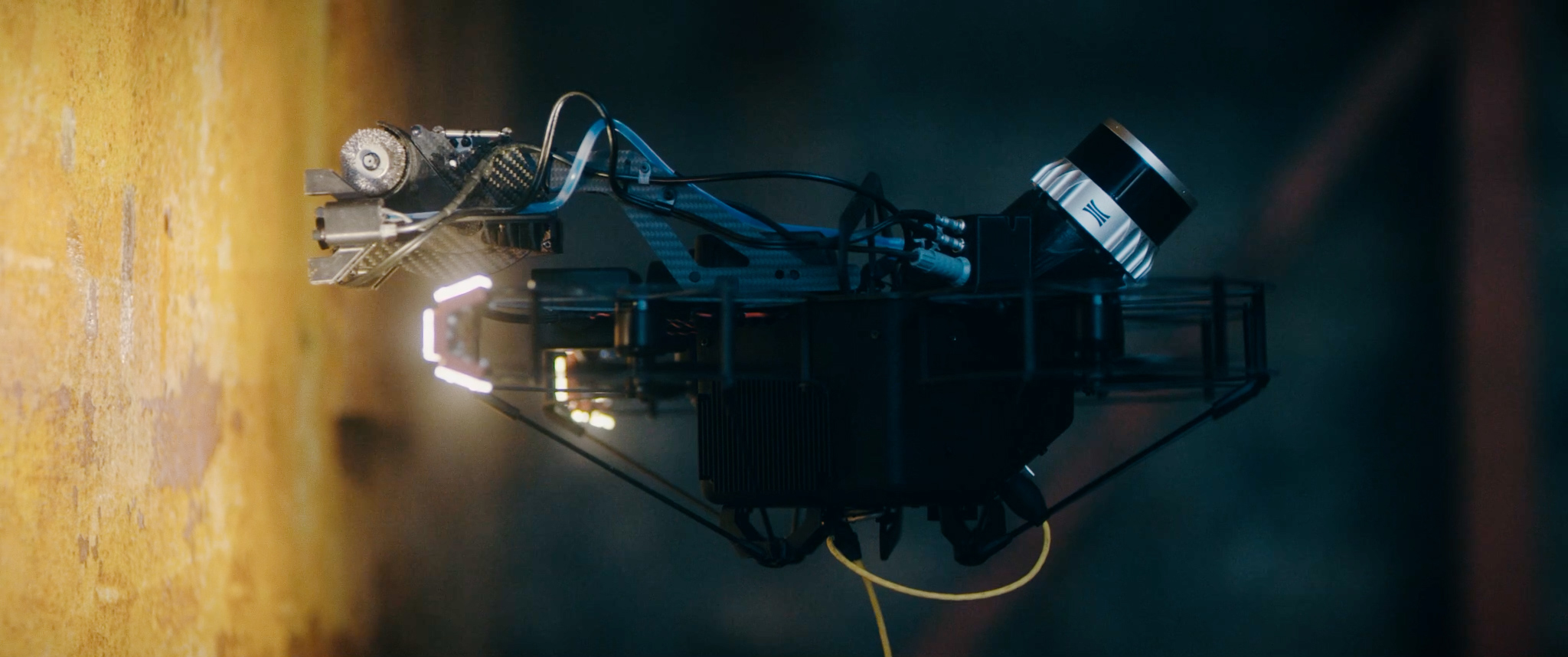

The Gen3 Scout 137 adds a survey-grade LiDAR, zoom camera, edge computing, more autonomy functions and evolved payload capabilities. The result is faster, safer inspections and data you can trust.

Gen 3 System highlights

✔ Rock-solid navigation with 128-beam 3D LiDAR and edge-based SLAM

✔ Crystal-clear visuals with 3.5x zoom and powerful LED lighting

✔ Optional UTM Payload w/ unique spot preparation module

✔ Teamwork made easy with dual-screen modes and the Scout Portal

“It’s clear that ScoutDI listens to their customers. You can see that heritage in this next-generation system“

Designed for non-stop performance

ScoutDI has been designing tethered drone systems since 2018. From the start, the tether has carried not only power but also control signals and data, providing a fully wired connection between pilot and drone, without the risk of RF dropouts and extra BVLOS fail-safe gear.

UTM Payload

Ultrasonic Thickness Measurements with live A-scan

This architecture has been proven in countless inspections lasting several hours without interruption. It ensures stable operation even in the most challenging environments, where wireless links often fail or require repeaters.

The platform supports mission-ready payloads, including a high-res zoom camera, an integrated gas sensor for continuous safety monitoring and the UTM Payload for surface preparation and measurement in one pass.

We deliver a system that operators can trust for endurance, reliability and safe performance in the toughest conditions.

Rock-solid hover

crystal clear data

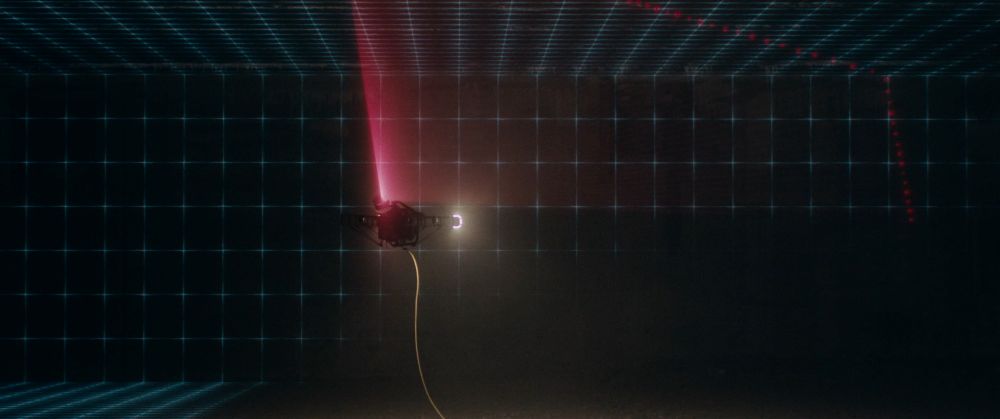

The Gen 3 Scout 137 combines a 128-beam Ouster 3D LiDAR with edge-based SLAM on a powerful NVIDIA computer, ensuring unmatched stability even in tight spaces

Automated flight patterns build on this foundation to generate consistent datasets for photogrammetry and automated analysis. Assistive modes maintain a controlled standoff to surfaces and guide systematic coverage for repeatable results.

The live point cloud and mini-map in the Scout Operator app keep the pilot oriented in GPS-denied spaces, enabling steady hover and accurate returns to the same point when required. Even when operating fully BVLOS.

High detail visuals

Equipped with a built-in 3.5x zoom camera with autofocus and supported by powerful Led lighting, the new Scout 137 captures detailed visuals even when obstacles prevent close access.

If multiple focus planes compete in the frame, the pilot can direct focus to the exact area of interest with a single tap.

UTM Payload with cleaning module

The ScoutDI UTM Payload is unique in the market, combining spot-preparation, couplant supply and ultrasonic thickness measurement in a single payload to cut UT inspection time in half.

Real-time parameter control from the pilot’s tablet keeps the operation efficient and uninterrupted.

Built tough for repeated contact, with a smart release function for safe undocking in tight spaces, it improves safety for both inspectors and equipment. This innovation has earned strong recognition from industry experts for making UTM safer, smarter and easier

A better inspection experience,

on-site and off-site

The Scout 137 has always been designed to be easy to fly, straightforward and stress-free. Rock-solid stability, automated flight patterns and onboard processing let the pilot focus on the inspection instead of constant stick work.

With our dual-screen options, the pilot and another specialist can work side by side – improving efficiency and ensuring the highest quality of data. Live streaming to the Scout Portal allows off-site experts to sit in on the inspection in real time, removing unnecessary travel, logistics and waiting times

What the customers are saying

Listen to what some of our customers are saying about the Gen 3 Scout 137 drone system.

These are experienced drone pilots and NDT inspectors who know the industry well, are using ScoutDI tools in their daily work and have operated several other drone systems.

Their perspective is rooted in experience and comparison. Hear them explain why they choose to move forward with the latest Scout 137 drone system

“For extended confined-space inspections, the ScoutDI drone is the one we rely on”

Simon Ruddick / Marine Inspection Services

Turning data to insights

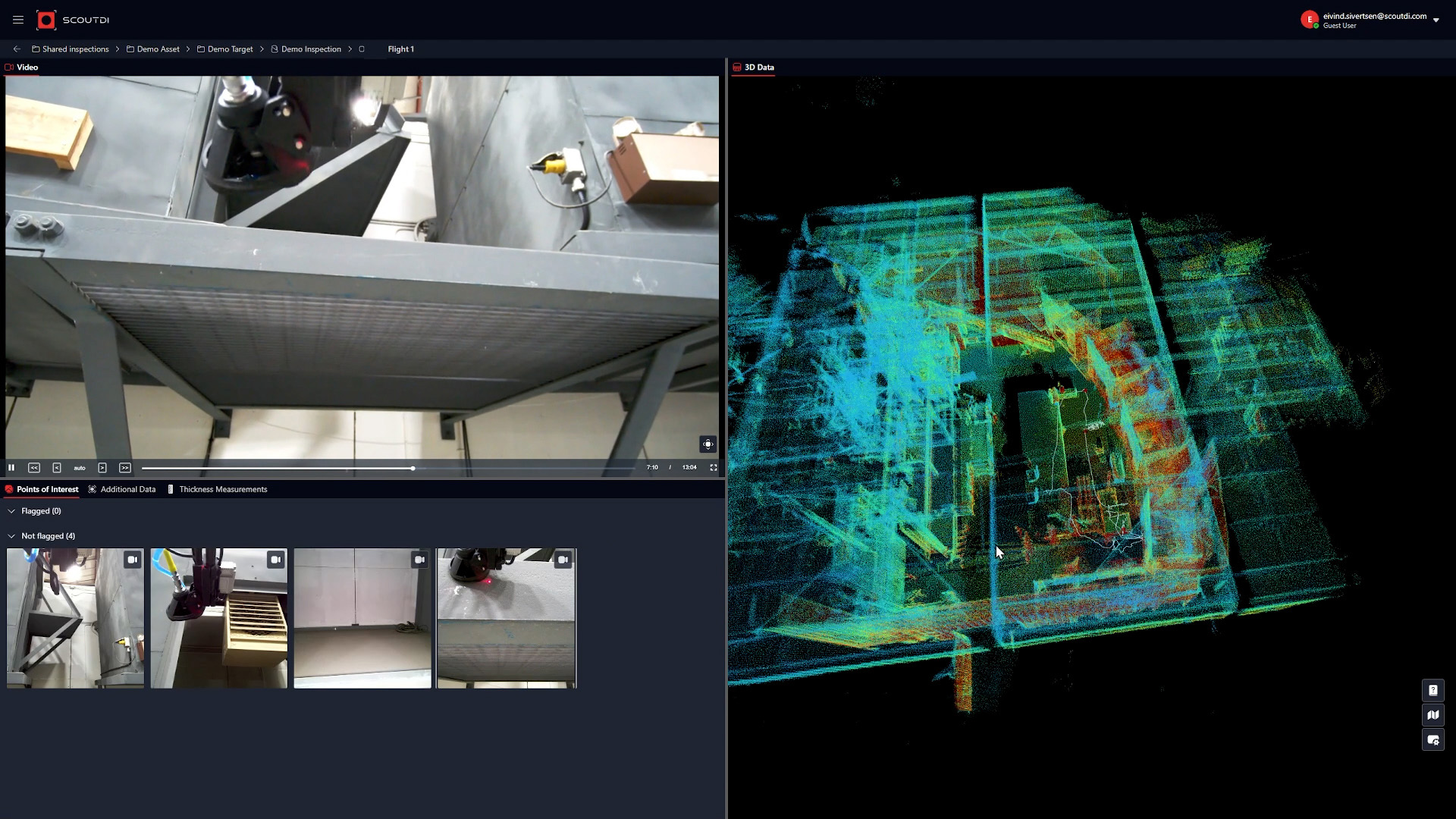

The Scout Portal lets you review, visualize, analyze and share your inspection data. All in one place, with your data securely stored and backed up in the cloud.

- Interactive 3D review with flight path, POI and UTM.

- Live streaming and remote collaboration.

- Secure cloud storage, backup and sharing.

- ML-ready for enhanced data analysis.