Ultrasonic thickness measurements in confined spaces are often slowed down by fragmented workflows. Surface preparation, probe calibration, couplant handling and measurement are typically treated as separate steps, frequently requiring repositioning, manual intervention or multiple tool changes. The result is longer inspection time and unnecessary operational friction.

With the Scout 137 Gen 3 and the Next-Generation UTM Payload, these steps are brought together into one continuous operation.

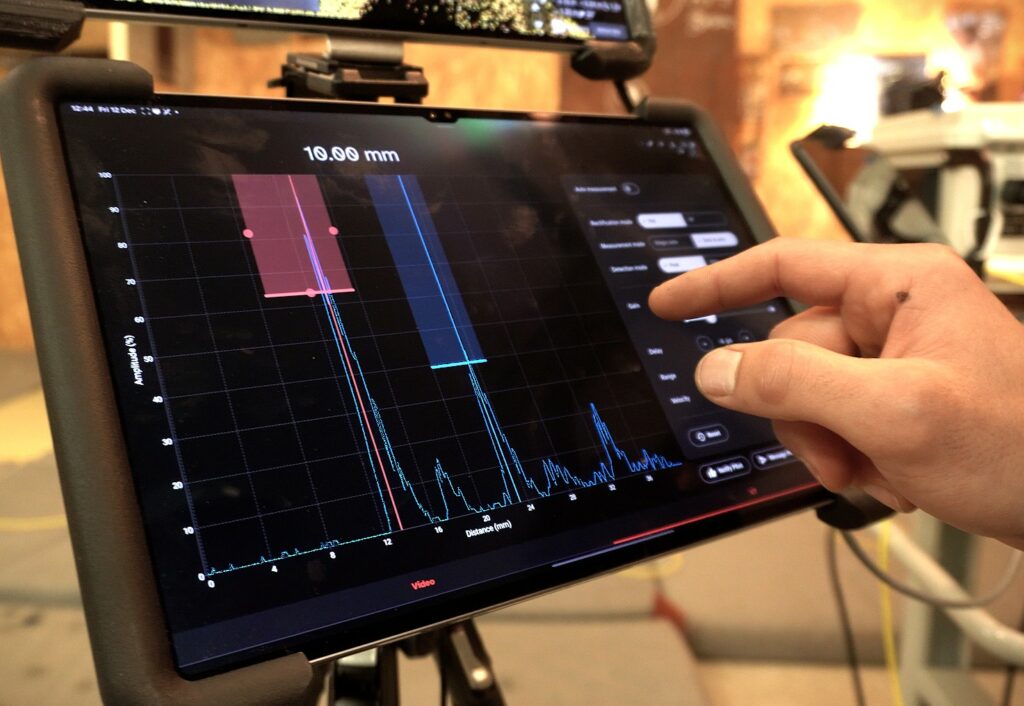

In the short example below, the system performs ten ultrasonic thickness measurements in under two minutes, starting with probe calibration and followed by repeated undocking, repositioning and measurement on the same steel plate.

In the case of this 10mm steel plate, which was in very good condition, couplant use was minimal. For this session with calibration and measurements, only 0.4 grams were used out of the approximately 30 grams carried.

Calibration and pulser control in one interface

The workflow begins with probe calibration performed directly in the Scout Companion app. Calibration, measurement control and live data feedback are handled through the same interface, reducing setup time and removing the need for separate tools or workflows.

This simplifies preparation and allows the inspection team to focus on the task itself rather than managing multiple systems.

Integrated spot cleaning and UTM

A key enabler for efficiency is the integration of spot cleaning, controlled couplant application and UT measurement within the same payload.

Instead of cleaning surfaces in advance or as a separate operation, the UTM Payload performs local surface preparation immediately before each measurement. This makes it possible to move directly from point to point, cleaning and measuring as part of one uninterrupted process.

The result is:

- Fewer manual steps

- Less repositioning

- More consistent and repeatable measurements

This integrated approach significantly expands the practical use of UT in confined spaces where access, time and safety constraints previously limited inspection scope.

Designed for confined and constrained environments

During the sequence, the UTM Payload repeatedly undocks and re-docks between measurements. The Smart Release mechanism keeps movements minimal during undocking, which is critical when operating close to structures or in tight geometries. This supports stable operation and predictable positioning without unnecessary motion.

Combined with tethered power, LiDAR-based navigation and high-resolution visual inspection, the system enables extended UT inspections without interruptions for battery changes or manual resets.

One continuous inspection workflow

By combining calibration, spot cleaning, couplant handling and UT measurement into a single workflow, the Scout 137 Gen 3 reduces inspection time while improving operational consistency. What would traditionally require multiple steps and tools can now be performed in one continuous operation.

For inspectors and asset owners, this means faster inspections, clearer data and fewer compromises when working in confined spaces.

👉 Learn more about the Next-Generation UTM Payload

Want to explore the cutting edge of drone inspection? Get in touch!

Contact us to learn more👍