Unlimited flight-time provides optimum working conditions and maximizes safety, efficiency and data quality 👍

Executive Summary

APPLUS+ has performed visual inspection of a very large (> 20 000 m3) cargo tank for a global oil & gas major, using the Scout 137 Drone System from ScoutDI. Applus were the first in Australia to use this equipment and have it approved under the Lloyds Register ‘Remote Inspection Techniques’ (RIT’s) certification scheme. The possibilities that Applus can offer their clients for future confined space inspections are greatly improved, whilst the unlimited flight time of the Scout 137 Drone is found indispensable.

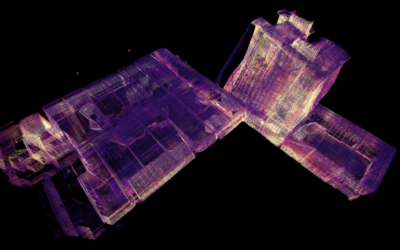

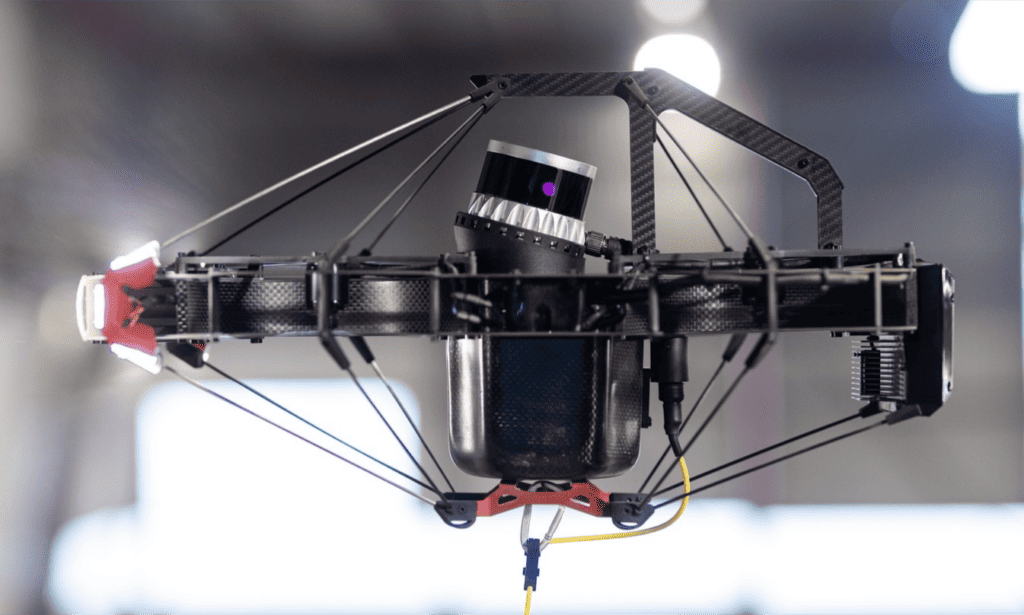

The Scout 137 has a 64-beam 3D LiDAR with a 90° opening angle and ~100 m range. This enables rock-steady positioning, reliable navigation and accurately location-tagged inspection data.

Safety benefits

Traditional inspections of a cargo tank of this size (> 20 000 m3) normally require 4-5 rope access technicians, with additional support personnel. They will be working at height, under deck for 4-5 days. These are exhausting conditions, with little ambient light and poor air quality.

This visual drone inspection was done flying the Scout 137 Drone System from the tank floor. The entire inspection job was completed in 1 shift and a team of 4 people were involved.

Based on findings from the visual inspection, subsequent NDT was performed via rope access with very targeted and reduced scope. The exposure of humans working at heights and other dangerous conditions is thus greatly reduced using confined-space inspection drone systems.

The Scout 137 Drone System from ScoutDI has a tether system that provides unlimited flight-time. The constant interruptions and stress related to frequent battery changes were eliminated by this and allowed more focus on the job.

Efficiency and operational benefits

Using drone inspection obviously reduces or eliminates personnel exposure, but also reduces production downtime, personnel transport and related logistics. Beyond the data acquisition, having well-planned continuous video footage makes data verification and analysis easier and faster.

High-speed internet being available at the inspection site added the benefit of live streaming via the Scout Portal. This allows off-site stakeholders to take part in the inspection remotely in real-time. Coverage approval, flight patterns and other immediate action can be planned while the crew is on-site, eliminating the need for costly and time-consuming revisits.

Data coverage and data quality

Drone inspection with the Scout 137 Drone System allows close to 100% data coverage in most cases, as the drone will be able to reach any area in the tank to capture video and photos at the equivalent of arm’s length, providing good spatial resolution and ample adjustable lighting.

Having unlimited flight time allows the pilot to focus entirely on the job and the resulting data.

📢 This case study has moved to live with its relatives, the other case studies.

You can click the button below to read the rest. It’s free and you don’t have to sign up for anything.

Would you like to know more about the Scout 137 Drone System?

Feel free to contact us using the form below! 👍