Executive summary

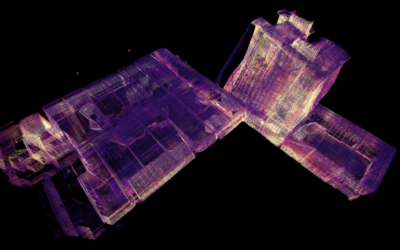

TDBR has performed visual inspection on a large FPSO offshore of Brazil, using the Scout 137 Drone System from ScoutDI. This being a large unit, the tethered solution of the ScoutDI drone becomes indispensable with its unlimited flight-time.

The job was to inspect deck transversals, nine in total, and the timing was communicated as “urgent” for the unit back into operation. The job was completed within a 2-hour time frame with the Scout 137 Drone System. A class society surveyor witnessed the inspection and immediately credited the tank afterwards.

Typical mid-size FPSO, not the one from this case study.

Safety benefits

For a large and tall unit like this, it is of particular importance to avoid the need for humans working at height. A team of two is sufficient to bring the equipment in and out of the asset and perform the inspection, reducing human exposure to the conditions in the tank tremendously.

Operational benefits and efficiency improvements

The Scout 137 Drone System has several advantages that benefit this type of job:

BVLOS inspection support by design means a larger part of the volume can be inspected without moving equipment and personnel around.

Unlimited flight time means that the crew does not need to interrupt the inspection job to change batteries. This provides extra advantages in terms of finishing the job sooner.

In this case, a team of two people completed the tank inspection in less than two hours with a minimum of moving.

Benefits to job completion and approval

A class society surveyor was present during the inspection, watching everything. Content with how the inspection was done, and how the system allowed him to confirm everything live on site, he credited the tank on the spot, immediately after the job was done.

📢 This case study has moved to live with its relatives, the other case studies.

You can click the button below to read the rest. It’s free and you don’t have to sign up for anything.

Would you like to know more about the Scout 137 Drone System?

Feel free to contact us using the form below! 👍