Case Study

Latana Chemical Tanker

Time Savings

Reduced asset down-time through flexible inspection regimes

Cost savings

Reduced cost by avoiding scaffolding, climbers and rescue teams

Safety

Improved safety by reducing need to enter hazardous areas

Quality

Improved data quality and situational awareness in data capture

Introduction

Chemical tankers are a type of tanker vessel that have either been specially designed or adapted to transport bulk liquid chemical products. These types of vessels are often seen in regular operation shuttling products along the coasts.

The tanks are often constructed in stainless-steel (for corrosion resistance) and may either be integral with the ship structure or may be separated by either single or double skin. In accordance with class rules, there are a number of general and specific inspection requirements to ensure the continued safe operation of the vessel.

The tether system allowed for continuous operation of the drone system and eliminated the risk of signal loss during flight.

Results

The Scout 137 drone was deployed to the vessel while it was in port. The vessel would only be available for a short time so the ability to carry out the inspection quickly and with minimal prep was a significant advantage.

Some of the other key advantages identified by using the Scout 137 for this application were as follows:

- The Scout 137 was able to provide complete coverage of the upper areas of the tank.

- Since time was a factor, the tether capabilities meant that crucial time was not lost by having to change batteries. This also maintained the continuity of the inspection data as the flight time was not broken up.

- Since the data link between the controller/tablet and the drone is routed through the ground station, this meant that a stable connection was maintained for the duration of the flight. When flying into areas where a wireless drone would suffer signal loss, the Scout 137 was able to be fully controlled and operated.

- The software anti-collision ensured there was minimal risk of damage to the stainless-steel structure.

Conclusion

The Scout 137 showed its suitability for tank inspection and provided the customer with a new capability as they “haven’t been this high in the tank before”.

The tether system allowed for continuous operation of the drone system and eliminated the risk of signal loss during flight.

As we continue the roll out of this technology with our customers and partners, we will unlock even more value from visual inspection capabilities of the Scout 137.

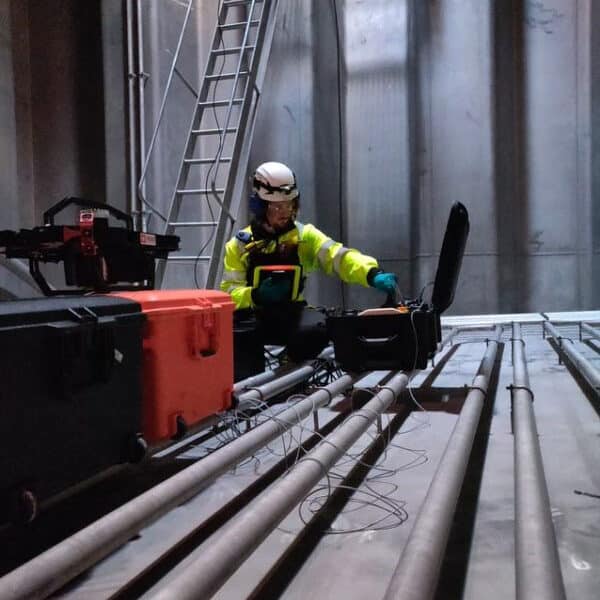

The Scout 137 Drone System inspecting the Latana Chemical Tanker

Would you like to know more about the Scout 137 Drone System?

Are you looking for drone-based inspection technology for confined industrial spaces? Submit the form to get in touch with us and we'll help you find options 👍

Learn More

Scout 137 Drone →

The Scout 137 Drone System has been specifically designed to give you control, coverage, and situational awareness for your confined space inspection activities.

Scout Portal →

The Scout Portal is our powerful cloud-based tool for inspection data management, review, analysis and reporting.