Safer turbine foundation inspections with better documentation

Executive Summary

Ørsted introduced ScoutDI’s tethered drone system for offshore wind turbine foundation inspections. The shift has supported safer inspection practices by reducing the need for confined space entry where drone access is possible, while providing more consistent digital documentation.

Key Results at a Glance

- Team size: Typically reduced from 4 to 3 people per turbine

- Inspection time: Reduced from approximately 2,5 hours to around 20 minutes for the internal turbine foundation segment.

- Safety: confined space entry avoided on sites where drone access is possible.

- Data volume and coverage: Much higher data density and more consistent coverage, improving year-to-year trend analysis.

Introduction

Ørsted is one of the world’s largest offshore wind operators, responsible for producing about a quarter of global offshore wind power. With such a scale, every inspection matters. Keeping turbines safe and upright requires reliable, repeatable checks.

When Ørsted looked for a better way to inspect turbine foundations, ScoutDI’s tethered drone system and digital inspection workflow were identified as a suitable approach for these inspections. Unlimited flight time, safe tethered operations and a digital inspection workflow offered a safer and more consistent way to perform the work.

The Challenge

Traditionally, inspections inside offshore wind turbine foundations involved confined and demanding working conditions:

Technicians would climb down into the foundation and amongst other things, measure the spacing between stopper plates, a critical indicator of structural movement over time. Conditions are typically damp and demanding.

These operations required a lot of resources and had some other shortcomings:

- Four persons per turbine, two doing the job and two for safety.

- Measurement locations varied between technicians, reducing year-to-year comparability.

- Stopper-plate readings were difficult to compare over time due to inconsistent positioning.

This approach meant long campaigns, repeated confined space entry, and inconsistent data that were hard to compare from year to year.

The Solution

Ørsted chose the Scout 137 Drone System for these inspections. Several factors contributed to the selection of the system:

Unlimited flight time with tethered power, so inspections could run smoothly without battery swaps.

Safety first: with drone accessibility, human access to the foundation can be reduced, and the tether ensures the drone could always be retrieved.

Responsiveness: At Ørsted’s request, ScoutDI integrated an Intel RealSense (R) stereo camera into the drone. This enabled precise, repeatable digital measurements of stopper-plate spacing, providing a digital alternative to manual readings that previously varied between technicians and improving year-to-year comparability.

For Ørsted, the stereo-camera upgrade addressed a critical measurement need: reliable stopper-plate spacing is key to understanding structural development over time, and the drone now delivers these measurements digitally and repeatably.

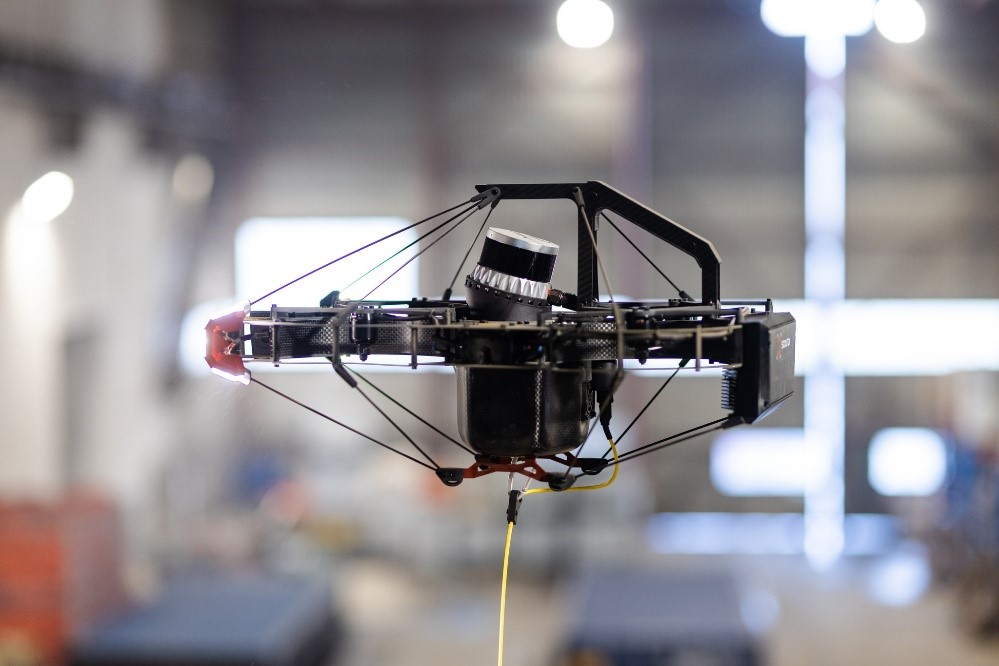

Generic Scout 137 Gen 2 Drone. The systems used by Ørsted are equipped with an Intel RealSense stereo camera for capturing stopper-plate positions.

Training took place in England with around 20 inspection technicians. These were experienced professionals, with limited drone experience, yet they quickly learned to operate the system. Ease of use was key to fast adoption.

Results

The new inspection workflow led to observable changes in how foundation inspections were carried out. Fewer personnel were required on site; inspection activities inside the foundation were completed more quickly, and the need for human entry could be avoided where drone access was possible.

In addition, the increased volume and consistency of digital data improved the basis for engineering review and year-to-year comparison.

This helps reduce offshore exposure for personnel and provides more consistent data for engineering follow-up.

Customer Perspective

According to Ørsted’s engineering team, the drone has improved documentation quality, increased data coverage and reduced the need for human entry in turbine foundations where access is possible. Stopper-plate trends will be easier to monitor from year to year.

Conclusion

For Ørsted, adopting the Scout 137 Drone System has supported improved repeatability and documentation quality, while reducing the need for human entry where conditions allow for turbine foundation inspections.

While the overall turbine-per-day rate remains unchanged due to other required tasks, the drone has strengthened data quality and reduced confined space entry where access allows. Operational results may vary depending on site conditions, access constraints, and inspection scope.

| Before (manual entry) | After (Scout 137 Drone Dystem) | |

| Safety | Personnel entered the foundation, with associated operational risk. | Confined space entry reduced or avoided where drone access is possible; tether supports controlled retrieval. |

| Efficiency | Approximately 2.5 hours per foundation inspection, typically involving multiple personnel. | Around 20 minutes for the internal turbine foundation segment, typically involving a single inspection team. |

| Cost | Four people per turbine, higher offshore man-hour exposure. | Typically, three people per turbine, with reduced offshore man-hours for foundation inspection activities. |

| Data volume and coverage | Limited visual documentation and variable coverage between turbines and inspection campaigns. | Higher data volume and more consistent coverage, supporting more reliable stopper-plate trend analysis. |

Over time, the system is expected to support even smoother campaigns as experience grows, and hardware continues to evolve.

Watch this video from Microsoft Partner Network (2022) and see how Cognite and Ørsted turned inspection data from offshore wind turbines into insights for predictive maintenance 📢

Built in Norway. Designed for the World.