NEXT-GEN PAYLOAD FOR ULTRASONIC THICKNESS POINT-SAMPLING

Engineered for reliability, repeatability and real data integrity

The ScoutDI UTM Payload combines automated surface preparation, precision ultrasonic gauging and controlled data management — all in one professional, tethered system.

From surface prep to verified data

✔️ Pro-grade surface preparation

Integrated rotating brushes remove coating and corrosion precisely where needed, with adjustable pressure and replaceable brush types.

✔️ Motorized probe arm with Smart Release

The probe arm keeps steady surface contact and lets the pilot adjust its angle in-flight to reach walls, ceilings and everything in between. It also has a motorized release that disengages the probe from the surface for safe retraction from tight spots.

✔️ Reliable ultrasonic measurement

Integrated Talisman™ UT probe from THORNETIX. Live A-scan and on-the-fly pulser control let qualified personnel judge measurement quality in real time, ensuring reliable thickness documentation in a continuous flow without manual save steps.

✔️ STRUCTURED UT DATA WORKFLOW

Each contact phase produces multiple UT readings that are grouped and location-tagged, letting you see exactly where they where captured. In post, you can review variations across each contact phase and pick the most representative values.

01. Position and prepare

The drone is positioned in front of the target area. The probe arm is aligned for surface contact, with the mini-map, point-cloud and onboard laser helping the pilot make a precise, safe approach. Permanent magnets keep the payload attached to magnetic surfaces.

02. Prepare and measure

The pilot triggers brushing and couplant delivery as needed. The system captures UT readings automatically throughout the entire contact phase, while the operator monitors the live A-scan to ensure good data.

03. Confirm and undock

Assessing the live A-scans, the operator confirms that usable readings have been captured. The probe arm is then disengaged using Smart Release, requiring minimal drone movement for a safer disconnect in tight spots.

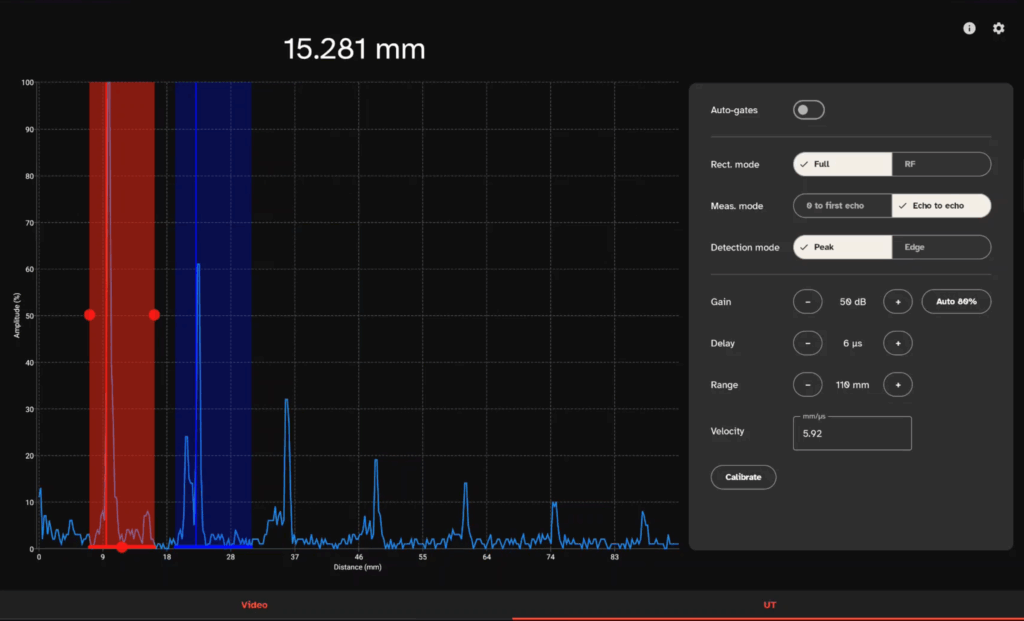

Live UT workflow with the Scout Companion app.

This clip shows a full UT contact cycle in our workshop.

You see the drone approach the surface, position the probe arm, prepare the spot and hold steady contact while ultrasonic readings are captured. During this phase, the operator adjusts UT pulser parameters live in the Scout Companion app to home in on the right echoes and get accurate thickness.

The sequence demonstrates stable contact and controlled UT acquisition in a confined test setup.

Integrated. Detachable. Ready.

The UTM Payload connects directly to the Scout 137 Drone System, sharing power, control and data through the tether.

It is fully integrated yet easily detachable, designed to work seamlessly alongside the drone’s 4K camera and Survey-grade LiDAR. No tools are needed to attach and connect the UTM Payload.

You can capture high-resolution video, 3D LiDAR data and Ultrasonic Thickness Measurements within the same flight, all location-tagged for precise correlation.

Built for real world jobs

The UTM Payload is designed for practical field work where conditions and objectives vary from job to job. It supports a range of interchangeable probes and brush modules, allowing operators to adapt quickly to different materials, coatings, and surface conditions.