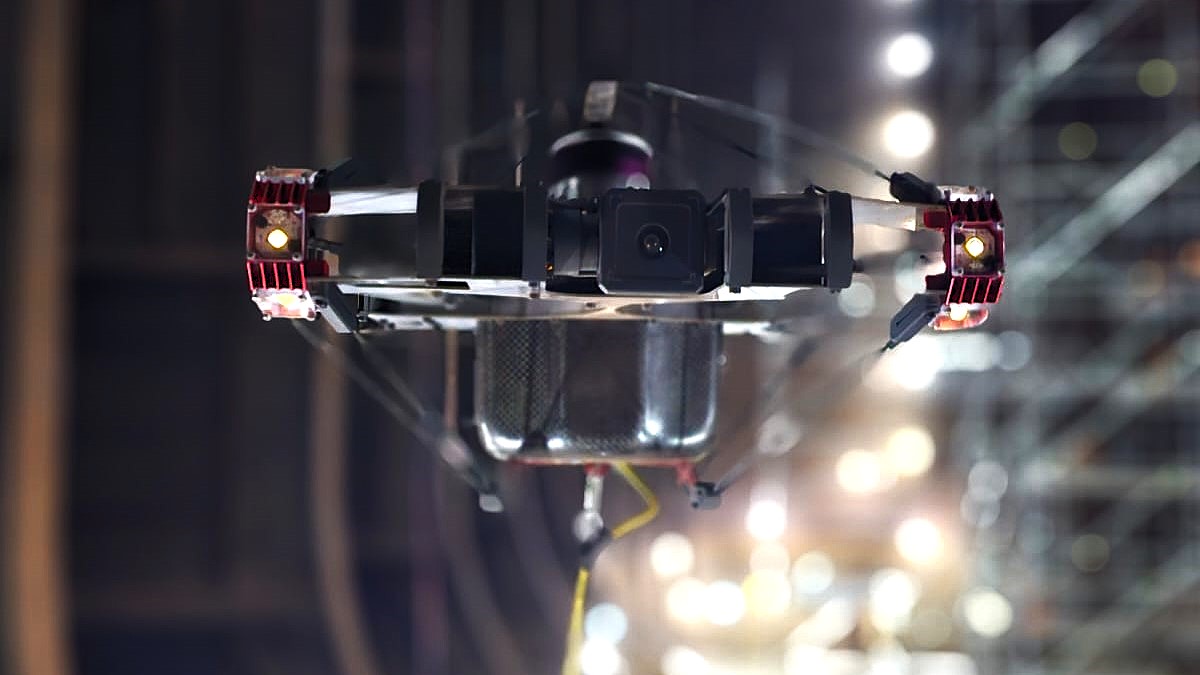

A confined-space inspection drone system with unlimited flight time

Scout 137 Drone System

Specifically designed for safety, control, coverage, and high-quality data for indoor inspections in industrial environments.

Revolutionize remote inspections

The Scout 137 Drone System is a professional tool for safer and more efficient remote inspection of confined spaces. Its cutting-edge 3D LiDAR technology provides automatic anti-collision and extensive pilot support for BVLOS operations. This drone eliminates the need for humans to work at heights or inside hazardous environments.

The drone is tethered to a Ground Station and carries no batteries. As a result, it has unlimited flight time and a fully wired, reliable control path. Not worrying about battery changes reduces external distractions and allows full focus on the job.

Available data options

An industry-leading 3D LiDAR sensor and high-resolution fixed-lens camera are standard parts of the Scout 137.

In addition, these optional payloads are available.

UTM Payload

Ultrasonic Thickness Measurements with live A-scan

Gas sensor

Flammable gas detection and warning

“ScoutDI is the most forwarding thinking drone company we have dealt with”

— Stein Hansen / IKM Testing

Ground station

The Scout 137’s tether system supplies continuous power to the drone and allows stress-free inspection with unlimited flight time.

No need to worry how much power is left. No more hassle with changing and recharging batteries. Take your time, stay safe and focus on the inspection.

Power options

The Scout 137 is powered by the Ground Station via the tether and does not carry Li-Ion or LiPo batteries. The Ground Station connects directly to wall power outlets, AC generators or Portable Power Stations.

Fully wired connection

The tether is not compromised by poor RF conditions or subject to unwanted data eavesdropping. You won’t lose your drone and you won’t lose your data.

Live streaming connectivity

Live inspection streaming is a useful work mode allowing on-site crew to cooperate with off-site stakeholders live during inspection. The Ground Station facilitates this via built-in RJ45 connectors for on-site internet and an included USB hub to tether your smartphone’s 4G/5G broadband.

Data examples

Explore real world datasets from inspections made with the ScoutDI Solution

Scout App & Controller

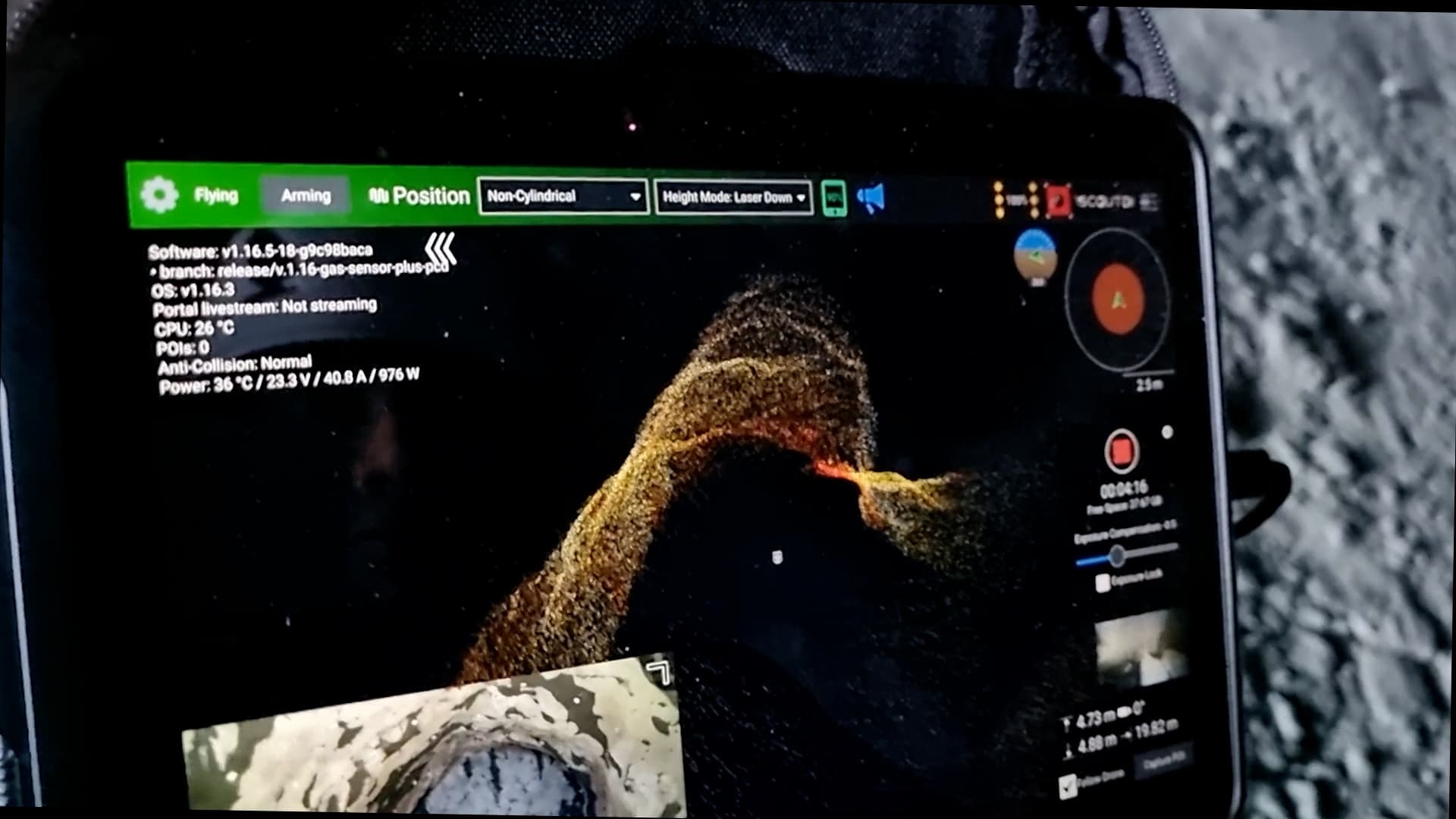

The Scout App provides full control of the drone’s system functions and displays camera feed, LiDAR point cloud and Mini-map in real time.

Due to the autonomy and navigation aids built into the drone system, you will be able to perform advanced flight patterns with simplified flight controls.

Full data payload integration

All available ScoutDI payloads are fully integrated with the tablet and controller to make the pilot experience as smooth and distraction-free as possible.

Of course, the normal flight controls are there. But there are also special functions for the data payloads, like UTM Payload probe head angle and Smart Release, gel pump etc.

Do you know how to get the best drone inspection footage? The secret is right there at your fingertips.

Visualize, analyze and share your inspection data

Scout Portal →

The Scout Portal is our powerful cloud-based tool for analysis, reporting, storage and backup of your confined-space inspection data. It has built-in SLAM and generates a 3D point cloud of the inspected asset to visualize all visual POI and UT measurements.

The 3D model allows you to look at it from any angle, zoom in and out and read the text captions. Click ▶️ to load model. Click and drag to rotate, ctrl/shift to zoom and slide.

Scout 137 Drone specs

| Dimensions, drone | 613mm × 382mm × 303mm (L×W×H) |

| Dimensions, transport case | 676mm × 525mm × 378mm (L×W×H), regular checked baggage |

| Weight | 3.3 kg |

| Camera resolution | 4K video, 3840 x 2160 @ 30 fps |

| Lighting Intensity | Over 12,000 lm |

| Camera Gimbal | 2-axis stabilized, ± 90° pitch |

| Tether Length | 40 m |

Ground Station Specs

| Dimensions | 385mm × 440mm × 245mm (L×W×H) |

| Weight | 8.75 kg |

| Input Voltage | 200 – 240 VAC, 50/60 Hz |

| Internet connectivity | On-site LAN or 4G/5G tethered via smartphone. |

| Ingress Protection | (Made to the specifications of IP54) |