Large-Scale Concrete Structure Data Collection with the Photogrammetry-ready Scout 137 Drone System.

Project highlights

- Efficiency gain: Drone inspection was ~50% faster with proprietary autonomy features from ScoutDI.

- Over 40 workdays saved.

- Safety: No scaffolding or work at height required.

- Data quality and coverage: 300,000 location-tagged, high-resolution images enabling consistent 3D photogrammetry and reliable crack monitoring over time.

The autonomy features Auto Surface Scan, Auto Line Scan, Auto Image Capture and Distance Lock are available with Software Release 2.2.

Summary

At a hydropower plant in northern Sweden, ScoutDI customer KIWA carried out large-scale drone inspections of concrete dam structures using the Scout 137 Drone System.

During the project, the system received a beta software upgrade introducing Auto Image Capture, Auto-Surface Scan and Distance Lock, which enabled efficient and continuous data collection. The outcome was a highly structured dataset, well suited for time-based comparison of inspection results, photogrammetry models and AI-assisted crack detection. After defining scan parameters, the pilot supervised the automated process as the drone performed systematic image capture at scale. This autonomous workflow increased inspection efficiency by about 50%, compared to manual flights, while maintaining consistent data quality and operator safety.

This case demonstrates how scalable autonomous drone-based inspections are reshaping public infrastructure maintenance.

The inspection site

Storfinnforsen Hydroelectric Power Station is a significant hydropower installation in Norrland in Sweden. Commissioned in 1954, it has an installed capacity of 112 MW and an annual generation of approximately 536 GWh. The plant plays a critical role in supplying renewable electricity to the region, contributing to Sweden’s ambitious sustainability goals. It is operated by Uniper, a leading international energy company focused on reliable and sustainable energy solutions.

Background: Maintaining structural integrity

With a 10-year inspection cycle, the dam is subject to detailed assessments of its massive concrete structures. Seasonal temperature shifts and fluctuating pressure from the water and bedrock cause the dam sections to tilt slightly back and forth over time. While this movement is to be expected, it creates stress patterns that can lead to surface cracks, posing a long-term risk to dam integrity.

To counter some of the environmental variables, the dam sections have been encased in protective cladding. This weatherproofing improves control over internal humidity and temperature, creating a more stable inspection environment.

Previously, such inspections required extensive scaffolding to map cracks manually across multiple sections of the dam, a time-consuming and high-risk method that offered limited comparability between inspection cycles. The introduction of drone-based inspection changes all this.

Before drones, the vast concrete structure was inspected using 3 parallel sets of scaffolding: Inspecting one compartment while setting up in the next and dismantling in the previous one. The process would take many months, with many types of risks involved. Using drones changed that. Adding autonomy changes the game again.

KIWA’s mission

KIWA, a global testing, inspection and certification (TIC) company, conducted high-resolution visual drone inspections of the dam’s massive concrete surfaces using the Scout 137 Drone System. The objective was to capture full-surface imagery, centimeter by centimeter, to generate photogrammetry models and enable digital crack analysis with advanced software.

ScoutDI’s role and technological advances

At first, the Scout 137 was flown manually by Kiwa in a systematic “lawnmower” pattern to cover the wall surfaces. While effective, this approach required the pilot’s full concentration over long periods of time. As the project progressed, KIWA’s pilot was given access to a beta release of ScoutDI’s new autonomous flight features, including Auto Surface Scan, Distance Lock and Auto Image Capture.

With these tools, the inspection shifted from demanding manual flying to a more automated workflow: The pilot positioned the drone, set scan parameters and monitored progress while the drone carried out structured image capture at scale.

This not only reduced workload and physical strain, improving the mission’s safety and strain on human resources, but also produced a highly regular dataset ready for photogrammetry and crack detection.

The third-Generation Scout 137 Drone System brings on the heritage of the second-Generation system, used in this case. It is going into full production in Q4, 2025. The autonomy features are available for both systems.

Scaling up: Endurance by design

The Scout 137 is designed for endurance at every level. ScoutDI’s tether system provides both continuous power and stable wired data transfer, but the value goes beyond this. From flight modes to payload integration and operator support, the system is built for continuous operations lasting many hours each day.

Endurance by design ties directly into automated flight patterns, which only deliver full value when they can run without interruption. By combining unlimited flight time with automation, the Scout 137 enables truly large-scale inspections, covering entire structures in a consistent and repeatable way without unnecessary pauses for battery swaps or maintenance.

Unlimited tethered power and precise flight control make the Scout 137 ideal for large-scale confined-space inspections like this hydropower dam. Now enhanced with autonomy for fully automated, consistent data collection.

Introducing Autonomy

Halfway through the inspection, the workflow shifted from full manual flying to a beta release of ScoutDI’s new autonomy features, including Auto Surface Scan, Auto Image Capture and Distance Lock. The pilot simply defined the scan area by marking the top and bottom points of the wall and selecting the sidestep width, and the drone then carried out the systematic coverage on its own.

By maintaining consistent speed, consistent motion patterns, and consistent framing through Distance Lock, the Scout 137 generated a highly regular dataset. This not only improved data quality but also reduced the strain of continuous manual flying, allowing the pilot to focus on coverage and monitoring.

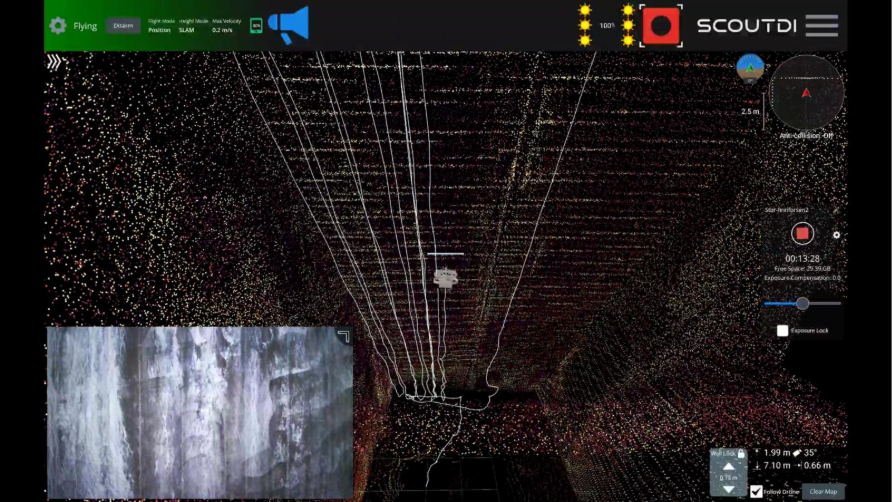

The pilot controls the Scout 137 Drone System via a controller and this tablet. The 3D point cloud, flight path and video feed are simultaneously visible on the screen in real-time .

Handling data at scale

With automation in place, the inspection workflow became far more structured and consistent. KIWA completed 52 flight hours inside the dam, capturing over 300,000 high-resolution images using the Scout 137 and its new autonomous flight functions.

The resulting dataset was exceptionally well suited for photogrammetry and digital crack analysis, which was carried out by Spotscale, a Swedish company specializing in 3D modelling and analysis, to support structural assessment over time.

Together, these efforts highlight a growing ecosystem of technologies that enable scalable, repeatable and data-driven maintenance of public infrastructure. As dams, bridges and tunnels face increasing demands for safety and lifetime extension, combining reliable drone-based acquisition with advanced analytical tools creates a powerful foundation for long-term asset integrity.

Results and impact

The automated flight and image-capture functions proved highly effective. The drone performed smooth, accurate zig-zag flights and maintained a steady distance to the surface, producing a structured and consistent dataset of 300,000 location-tagged, high-resolution images.

Based on the initial inspection of the two largest compartments, KIWA recorded 52 flight hours in total. After introducing the new autonomy functions, the same working time resulted in approximately 50% greater coverage compared to fully manual operation. This corresponds to just over three working days saved on the two first compartments. For the remaining 78 smaller compartments, the same efficiency gain represents an estimated saving of around 40 working days in total.

According to asset owner Uniper, previous scaffolding-based inspections required risky work at height over several months, including both the scaffolding and the inspection itself. Drone-based inspection has replaced this process, fundamentally improving safety, cost efficiency and data quality. The new autonomy functions further enhance all these aspects.

This screenshoot from the tablet clearly shows the “Auto Surface Scan” pattern flown by the drone. “Distance Lock” keeps the specified distance to the front surface, even if it’s slanted or curved.

Conclusion: Advancing public infrastructure inspection

This collaboration demonstrates how advanced robotics, autonomy and digital analysis can converge to meet the inspection needs of long-lifespan, high-risk infrastructure assets such as dams.

The project confirms the value of the photogrammetry-ready Scout 137 Drone System, combining unlimited tethered endurance and autonomous flight with automated image capture to deliver structured, repeatable datasets.

These high-resolution, location-tagged still images form an ideal foundation for accurate photogrammetric 3D models and AI-assisted crack detection, enabling consistent comparison of structural conditions over time.

This approach ensures safer, more efficient and data-driven inspections, extending the lifetime of vital public infrastructure while safeguarding inspection personnel.

Want to explore the cutting edge of drone inspection? Get in touch!

Contact us to learn more👍